Tag Archive for: schuberts

Yorke Towne, Toronto, Test Centre Sees Additional Install

Yorke Towne Supplies Ltd, Schuberts’ sole agents for Ontario, Canada have just taken delivery of the next phase of the new production-spec Test Centre.

The fully integrated ATEX CSA system features a manual smart booth spray system. This constantly monitors and automatically adapts the airflow and pressure differential inside the spray zone, keeping dust out, vapours inside and overspray drawn into the extraction filters. The system makes up for doors being opened, quality and saturation of the filtration system and changes in factory pressures (dust extraction, loading bay doors etc)

A flash-off section connects directly to the spray enclosure and allows coated product to flow out, settle and vent before going into the Schubox for rapid drying. The flash-off features filtered air input and low level extraction, again with 1000 lux lighting sets.

The Schubox completes the Test Centre, allowing either solvent or water based coatings for wood, glass, PVC, GRP and composites to be rapidly dried, at low temperature in record time. Utilising CSA and ATEX approved gas catalytic log wave infra red emitters, the Schubox can run from 30c to 50c and in combination with BA stainless, fireproof carcass, filtered air input and a unique recirculating airflow inside the Schubox.

For more information and to run trials in the Yorke Towne Canadian Test Centre, email scesario@yorketowne.com or call +1 905-762-1200

SWC Invest In Schubox System

Family run since 1989 and based in Scarborough, SWC Trade Frames is a large regional fabricator of premium quality PVCu & Aluminium windows, doors, conservatory roofs and specialist products such as vertical sash sliding windows, shaped frames and composite doors. They manufacture in excess of 1000 frames per week and supply exclusively to the Trade.

Coating and finishing is key to SWC giving their customers colour choice and with the massive rise in painted finishes, SWC have had a new custom Schubox gas catalytic IR drying system installed in their factory.

The new Schubox will slash drying times for both solvent and waterbased PVC and GRP coatings from multiple hours to just 45 minutes. The Schubox uses an intrinsically safe gas catalytic infra-red technology to cure the coatings very rapidly at a low temperature of 35-38c. This improves quality, reduces work in progress and means the turn-around time for sprayed product is cut dramatically.

Rhys Richings, MD of SWC says “The Schuberts guys from start to finish were fantastic & we’ll certainly pass on our recommendations”

Chris Widdowfield, Engineer at SWC says “Had the pleasure of engaging a very professional, friendly, and knowledgeable team of installation engineers this week. A lovely job well done. Thank you Schuberts.”

For more information, email sales@schuberts.co.uk

NEW!!! Automatic GRP Door Prep Brushing Machine

Is manually prepping GRP doors taking time, lots of labour and creating dust everywhere?!

We have a new custom designed fully automatic through-feed brush prep machine. 90+% of the whole door (even the deep recesses) is mechanically prepped before your wet prep clean and then sprayed.

2 doors per minute = 200+ GRP door slab faces per day…!

5+m/min, unique Flex-Trim brushes and some key differences from all other wood sanding machines!

All in for £28k?! Send us an email for details…

sales@schuberts.co.uk

Schuberts Install a New Giardina Automatic Glass Spray System at Esquire Glass

Founded in 1970 Esquire Glass has become one of the UK’s leading independent glass processors.

Their core business is in the production of processed glass panels for the kitchen, bedroom and bathroom industry. However, since 2002 substantial investment in a second factory and ‘state of the art’ glass processing plant has led to the company’s accelerated growth into new markets.

Their newest investment has been on a cutting edge finishing system from Giardina Group and their UK partners, Schuberts.

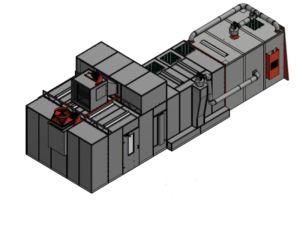

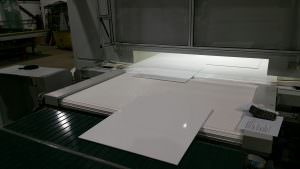

Running with waterbased coatings, the new Giardina system is capable of using both solid and far more difficult metallic colours. Fitted with 2 independent spray circuits, the switch between colours and coatings is very quick, meaning the customer can do both long and short runs of glass. All of the Wagner guns have the ability to run different tips and pressures, making the coating control very accurate.

The Dualtech 416 machine has full belt overspray recovery system, meaning wasted coating can be safely removed from the main belt, filtered and re-introduced into virgin mixes. The recovery system, unlike other systems relies on a series of rubber squeegees that gently, but effectively removes paint, rather than harsh metal blades that scrape and damage the belt over time. This guarantees the longevity of the Giardina belt.

The machine also boasts double filtration for the air input system, making the spray zone a clean zone, meaning reworks are a thing of the past.

On the extraction side, there are triple levels of filtration, ensuring incredibly low particulate emissions to atmosphere.

The touchscreen control panel gives the operators fine control over line speed, spray guns, circuits, pressures, gun heights and many other key parameters used for coating – all at the touch of a finger!

Once sprayed, the glass goes through a flash-off section and then on to a combination drying oven. The glass comes off the end of the line perfectly coated, dry and ready to handle and with a footprint of just 14m from end to end, it really is a compact, high production finishing system.

Paul Lockett, MD at Esquire says:-

“ Realising we (Esquire Glass) needed to be more flexible in the painting of our glass products, we spent last summer conducting due diligence on various systems. We found the Giardina system in collaboration with Schuberts UK to be the most effective for our needs. It was installed at the end of Jan ’18 and has already shown huge benefit by taking our production from 400 to 1600 pieces per shift. So far, we are very happy with the machine and are looking forward to developing it’s use over the coming year”

For more information on high quality glass processing and painting, email Esquire Glass sales@esquire-glass.co.uk

For more information on Giardina range of finishing equipment email sales@schuberts.co.uk