Epistolio Robotic Spray Systems

Epistolio Robotic Spray Systems

Schuberts install anthropomorphous robots from EPISTOLIO Robots for the automatic application of paints, lacquers and powders across all industry sectors.

Epistolio Robots are available in five axis models with direct self-learning programming or more sophisticated six axis models with point-to-point programming, self-learning, off line or external control systems.

Data logging, trending programming and robot integration into existing systems is also available from Schuberts.

Both five and six axis Epistolio robots are available in full ATEX specification for hazardous location use.

With its direct self-learning programming the operator guides the robot manually, via a joystick, through a complete spraying cycle on a sample piece. The robot PLC stores the data and commands and can then repeat them faithfully at the required speed. Small adjustments to this programme can also be made.

All robots have versatile mounting options for a variety of application guns.

MRK PAINTING ROBOT SERIES

MRK PAINTING ROBOT SERIES

The MRK painting robot series are flexible, user friendly and customisable.

MRK robots allow:

MULTIPLE PROGRAMMING SYSTEMS.

MRK robots can be programmed point to point for accurate painting of geometrically simple pieces, or self-learning for fast and easy painting of complicated shapes.

VARIOUS ROBOT CONFIGURATION.

The MRK painting robot can be integrated with multiple devices which are engineered and produced by EPISTOLIO Srl. These devices include carousel systems, external carriages and rotation devices.

DIFFERENT ARMS LENGTH.

To fit available space in the spraying booth and also the dimensions of the objects to be painted, they can be produced with arms of differing lengths.

SUPERIOR MANEUVERABILITY.

SUPERIOR MANEUVERABILITY.

The robot arms are built with very light but strong materials and are pneumatically balanced in order to achieve high levels of manoeuvrability during the programming stage.

JOYSTICK.

The self-learning programming system is simple and quick , thanks to the use of an ergonomic joystick which includes few programmable buttons, allowing a single operator to manage the entire programming stage directly from the painting area.

HIGH QUALITY.

HIGH QUALITY.

The painting robot MRK 6.1 is built with high quality materials and parts. Each mechanical component, driver, motor and gearbox come from the most important brands in the industry in order to ensure a long operating life.

CUSTOMIZED SOFTWARE.

Multilingual software which manages the robot has can be customized in order to perfectly meet your requirements. Moreover it includes a module for the management of the production filled with statistics and data. All robots are equipped with an industrial PC with touch-screen, in order to obtain a practical and intuitive management of all the functions of the machine.

SAFETY DEVICES.

SAFETY DEVICES.

Painting robots can be supplied complete with protective fences, systems for monitoring the operative area of the robot and to safeguard the safety of the operators. If required, they can also be constructed in explosion-proof version.

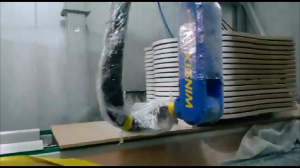

WINSIX ROBOT SERIES

WINSIX ROBOT SERIES

WINSIX robots are the top of the range, highest quality and robustness for maximum reliability and are fully integrated with software to provide a complete painting process solution.

Used for applications with VISION SYSTEMS or OFFLINE PROGRAMMING, for extra precision in the painting process, or working in a larger area.

EPI-WINVISION:

EPI-WINVISION:

Is a 2D (optional 3D) system used for the automatic painting of windows and doors. EPI-WINVISION is able to scan the image of the windows while they are moving on the conveyor and to send the data directly to the robot, which will immediately elaborate them and create the painting program, using some parameters set by the operator.

EPI-3DVISION:

A hardware and software package for the analysis and partitioning of 3D surfaces through cameras or laser scanners. The primitives generated by the software are processed in order to obtain an optimised painting path. Depending on the type of pieces to be painted, different recipes can be saved by managing numerous parameters of robot and spraygun set.

EPI-SIMULATION:

EPI-SIMULATION:

This software allows robot programming to be made using only a personal computer.

The robot is programmed like a CNC machine, starting from a CAD/CAM base which is used to import the 3D drawing of the piece to be painted and generate the path of the tools. After which, EPI-SIMULATION simulates the created program in a 3D environment and converts it into the language of the robot.

WINSIX robots can be supplied with a WORLDWIDE WARRANTY, with skilled technicians and spare parts available in most countries. Moreover, before or after the delivery, we can organize courses of different levels for the training of the people who will have to work with the robot.

WINSIX robots can be supplied with a WORLDWIDE WARRANTY, with skilled technicians and spare parts available in most countries. Moreover, before or after the delivery, we can organize courses of different levels for the training of the people who will have to work with the robot.