Schuberts Manufacturing Business Gains ISO9001 Certification

Setting the Bar High: Orange Box Finishing’s ISO9001:2015 Certification.

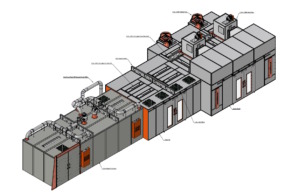

Schuberts wholly-owned manufacturing company, Orange Box Finishing has been awarded ISO9001:2015.

At Orange Box Finishing, we don’t just talk about quality — we prove it with our ISO9001:2015, fully audited, global certification. Whilst some suppliers are stuck in the past, we’re raising the bar and setting new standards for excellence in finishing services.

Here’s why our ISO9001 certification gives us a competitive edge:

- Reliability: Our ISO9001 certification isn’t just a piece of paper; it’s a guarantee of reliability. Some may promise quality, but we deliver it consistently, meeting stringent international standards at every step.

- Customer Confidence: When customers see that we’re ISO9001 certified, they know they can trust us. We don’t just meet their expectations; we exceed them, providing peace of mind and assurance that their projects are in capable hands.

- Efficiency: ISO9001 isn’t just about quality; it’s about efficiency too. We streamline our processes, reduce all our waste, and optimise productivity, delivering top-notch results faster and more cost-effectively than our non-certified competitors.

- Continuous Improvement: With ISO9001, we’re always improving. We don’t rest on our laurels; we seek out opportunities to enhance our operations, innovate our manufacturing techniques, and stay ahead of the curve, making sure we’re producing the best industrial finishing systems on the market.

So why settle for second best finishing systems when you can choose Orange Box Finishing? Our ISO9001:2015 certification isn’t just a mark of quality; it’s a symbol of our commitment to excellence and our determination to outshine the competition at every turn.