Tag Archive for: schubox

GRP Door slab manufacturer invests in their finishing future with Schuberts.

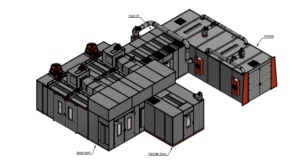

A significant, new, turn-key finishing installation has been commissioned at one of the UK’s leading GRP door slab, ancillaries and plastic components manufacturers.

The equipment comprises of a stand-alone horizontal automatic brush preparation machine. This through-feed machine uses Flex-Trim abrasive brushes to prepare the surface of the substrate. This then allows the slabs to be cleaned and then chemically prepared, ahead of coating. The through-feed brushing machine runs at 3m/min, meaning 380-400 sides can be processed per shift.

A load/unload automatic lifting station, when product up to 100kg each can be loaded and unloaded from the line with a single man.

The overhead conveyor is installed throughout the complete installation and with a max load on each 4 wheeled trolley of 200kg and a 90 degree sprung fitting for rotation.

Once loaded onto the line, a full ATEX rated spray enclosure with filtered air input and auto balance smart system has been installed for the spraying of the products. Individual silder divider panels are used to split up the spray zone into sector specific areas, allowing each of the potential 2 sprayers to spray at the same time.

Filtered air input, means all the incoming air for the spray process has airborne contamination removed, meaning no inclusions on the wet pieces being coated.

The inverter driven input and extract ATEX rated centrif fans are connected directly the PLC in the control panel and constantly alter their output depending on air pressures, filter condition and spray velocity required.

Once sprayed, the pieces go into a separate flash-off zone, where the coating is allowed to settle, vent and find its own level. Again, filtered air input means the wet product is kept clean and clear of particulate.

After the flash-off, a custom dimensioned Schubox is utilised for very rapid drying of the coatings. Running at just 36c, the gas catalytic IR heaters produce long wave infrared and along with a unique airflow inside the Schubox, the coatings are dried very quickly – around 45 minutes compared to 18 hours in ambient.

A dedicated ATEX rated paint mix room completes the installation. Bunded floor, ATEX heating, permanent extraction, filtered air, doors, work bench and ducting all feature in the PMR.

For more information on custom design manual and automatic spray finishing systems, email sales@schuberts.co.uk

Yorke Towne, Toronto, Test Centre Sees Additional Install

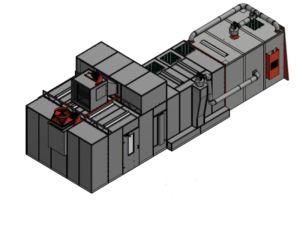

Yorke Towne Supplies Ltd, Schuberts’ sole agents for Ontario, Canada have just taken delivery of the next phase of the new production-spec Test Centre.

The fully integrated ATEX CSA system features a manual smart booth spray system. This constantly monitors and automatically adapts the airflow and pressure differential inside the spray zone, keeping dust out, vapours inside and overspray drawn into the extraction filters. The system makes up for doors being opened, quality and saturation of the filtration system and changes in factory pressures (dust extraction, loading bay doors etc)

A flash-off section connects directly to the spray enclosure and allows coated product to flow out, settle and vent before going into the Schubox for rapid drying. The flash-off features filtered air input and low level extraction, again with 1000 lux lighting sets.

The Schubox completes the Test Centre, allowing either solvent or water based coatings for wood, glass, PVC, GRP and composites to be rapidly dried, at low temperature in record time. Utilising CSA and ATEX approved gas catalytic log wave infra red emitters, the Schubox can run from 30c to 50c and in combination with BA stainless, fireproof carcass, filtered air input and a unique recirculating airflow inside the Schubox.

For more information and to run trials in the Yorke Towne Canadian Test Centre, email scesario@yorketowne.com or call +1 905-762-1200

SWC Invest In Schubox System

Family run since 1989 and based in Scarborough, SWC Trade Frames is a large regional fabricator of premium quality PVCu & Aluminium windows, doors, conservatory roofs and specialist products such as vertical sash sliding windows, shaped frames and composite doors. They manufacture in excess of 1000 frames per week and supply exclusively to the Trade.

Coating and finishing is key to SWC giving their customers colour choice and with the massive rise in painted finishes, SWC have had a new custom Schubox gas catalytic IR drying system installed in their factory.

The new Schubox will slash drying times for both solvent and waterbased PVC and GRP coatings from multiple hours to just 45 minutes. The Schubox uses an intrinsically safe gas catalytic infra-red technology to cure the coatings very rapidly at a low temperature of 35-38c. This improves quality, reduces work in progress and means the turn-around time for sprayed product is cut dramatically.

Rhys Richings, MD of SWC says “The Schuberts guys from start to finish were fantastic & we’ll certainly pass on our recommendations”

Chris Widdowfield, Engineer at SWC says “Had the pleasure of engaging a very professional, friendly, and knowledgeable team of installation engineers this week. A lovely job well done. Thank you Schuberts.”

For more information, email sales@schuberts.co.uk

UK Timber Door Manufacturer Goes the Schubox Route

One of the UK’s market leading supplier of wooden doors and associated products has just installed a new finishing system from Schuberts.

Their brand name can be found in the most prestigious names in the Builders Merchants and Retail sectors across the UK with in excess of 400,000 internal and external doors sold per year.

The new system comprises of two custom dimension centrifugal spec spray booths with canopies, lighting and custom duct work, plus a new custom Schubox gas catalytic infra red drying system. The input air is pre-filtered through capture and hold filters in the spray shop sliding doors.

The doors are pre-sanded, base-coated in the spray booths, dried in the Schubox, then denibbed, top-coated and back into the Schubox one final time.

Typical Schubox drying times with their high-build waterbased coatings are just 30 minutes at 35c, cutting previous drying times down from 3-4 hours per coat!

For more information on how Schuberts can streamline your finishing processes, email sales@schuberts.co.uk