MDF Producer installs Giardina Spray Line and Schubox Drying System

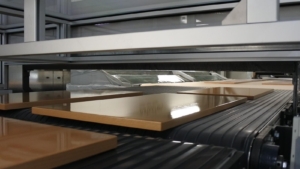

With over 100 different profile sections to deal with, a new coating and drying system has been installed by Schuberts to keep up with a massive increase in high quality painted MDF and timber. From 20mm to 300mm widths and up to 4600mm long, the new system will deal with it all.

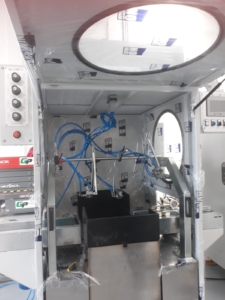

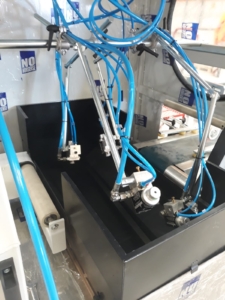

The new system comprises of a brush sanding machine, connected to a Giardina profile spray machine, all running at 35m/min. The 1VE spray machine in fitted with Wagner spray equipment and will do a full colour change in around 5 minutes and is able to deal with 1k or 2k coatings. 1k coatings can be recovered, filtered and blended back into virgin paint.

Once sanded, the profiles are then coated with waterbased 1k paint, taken off and loaded onto trolleys.

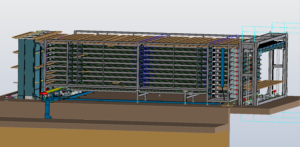

The trolleys are then placed into a custom dimension Schubox for rapid and safe curing of the coatings at 30-34c. Drying the paint at low temperature and quickly with the gas catalytic IR technology means no fibre raise, no damage to the coating and no movement in the MDF or timber.

The new system doubles production rates, dries coatings in a quarter of the time it used to and gives a much higher end quality.

For more information on high-productivity coating systems, email sales@schuberts.co.uk