Schuberts have just installed a turn-key Giardina autospray line at Virtuoso Doors as well as their older manual finishing system.

The philosophy of the new line was borne out of extensive testing and trials at our Sheffield Test Centre and proved to the customer there was only one solution that would work.

A cantilevered loading table at the start of the line starts the process, followed by infeed conveyor and then mechanical brushing with the brilliant flex-trim systems. The brushing machine has oscillation, speed, direction and height controls as well as a vacuum bed. This ensures the best surface preparation.

After brush sanding, there is an open section to allow application of prep-clean liquid before the cleaning and de-ionising process.

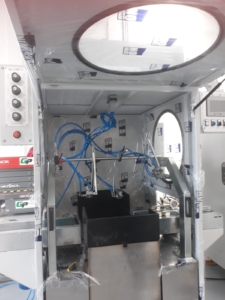

The spray machine 420 dry is fitted with 2 circuits and Wagner pumps and guns to give a consistent and even coverage of the coatings. This machine is processing full size doors as well as components.

Once sprayed, the products enter a flash-off tunnel, with incoming air is filtered, the air warmed to 30c and the paint vapours extracted to atmosphere.

After the flash-off, the products go through a jetted air tunnel at 45-50c for drying.

This new Giardina line from Schuberts goes hand in hand with the original manual system consisting of sprayshop enclosure with full autobalance, flash-off, Schubox drying system and paint mixing room.