New Schuberts Gas Catalytic Powder Coating Pre-gel Oven Installed

One of the world leaders in switchgear and energy management systems has just taken delivery of a new Schubert gas catalytic infra red pre-gel oven. The project was completed in association with systems partner TSD(UK) Ltd, for their existing powder coating line.

The Schubert pre-gel powder coating gas catalytic oven is designed to give a very rapid ramp up in heat energy prior to entering a conventional hot air oven. This rapid temperature gain is through the use of gas catalytic emitters and means that the overall coating line can be run much faster and with a much more even distribution of energy, the gelling and flowing of the powder gives a better surface quality and adhesion.

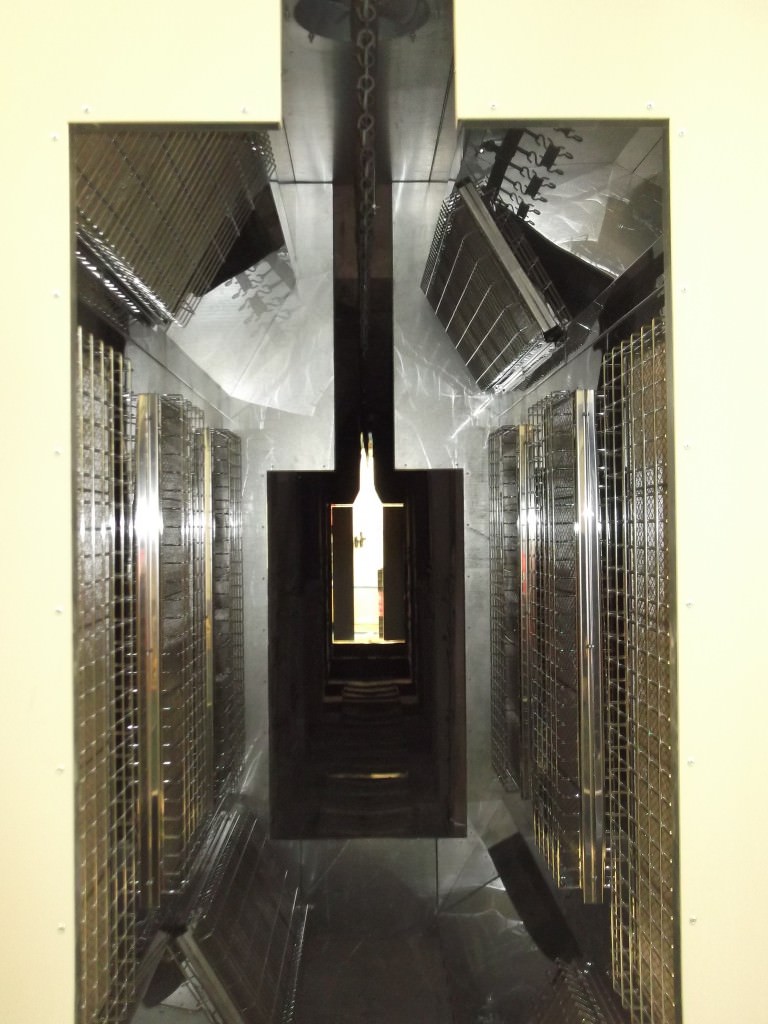

Process air is filtered to ensure that powder/dust is kept out of the gas catalytic pre-gel tunnel. The air pressure inside the tunnel is controlled through an air damper system and then extracted through a high temperature fan and ducting set to atmosphere. This combination ensures the oven is kept clean and the air recirculation system increases the efficiency of the oven.

The control that the customer has with this Schubert pre-gel oven is precise. With a rapid reaction time for each of the recipe settings, the pre-gel oven can quickly change output and profile to suit production.

Schuberts use highly polished stainless steel to reflect and refract the long wave infra red around the pre-gel tunnel, meaning that all faces of the powder coated product are subjected to an even and rapid energy rise.

The footprint and efficiency of a pre-gel oven is the key to its success. For example, with a traditional hot air system running at a line speed of 2m/min, we can increase the line speed by 40-50% with the addition of a 3-4m long pre-gel tunnel. Compared to traditional flame gas tunnels, this is a tiny footprint and with efficiencies of 60% better than flame gas systems, the Schubert gas catalytic pre-gel system has a very quick payback.

The pre-gel system shown in the attached photos is just 3.0m long, has a potential output of 105kw/hr and with our gas catalytic technology allows the powder coating line to run at a 40% faster line speed. No other modifications to the line were required, just a simple retro-fit of the pre-gel!

For more information, contact sales@schuberts.co.uk or call 00 44 (0) 1226 360900