Advanced Machinery and Schuberts UK, Announce Exciting New Joint Venture for the USA: Elevated Finishing www.elevatedfinishing.com

Advanced Machinery, a leader in cutting-edge manufacturing solutions, and Schuberts UK, a renowned provider of innovative finishing solutions, are thrilled to announce their strategic partnership in a groundbreaking venture named “Elevated Finishing.” This collaborative endeavour is set to revolutionize the industrial finishing industry in the USA with cutting-edge technology and unmatched expertise.

Elevated Finishing: Elevating Your Product’s Appeal.

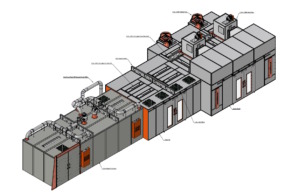

Elevated Finishing represents a fusion of Advanced Machinery’s expertise in precision manufacturing equipment and Schuberts UK’s mastery of standard and custom-built finishing solutions. This venture aims to redefine how products are coated, dried and finished, elevating the quality and efficiency of the entire process.

Key Highlights of Elevated Finishing:

State-of-the-Art Technology: Elevated Finishing will leverage Advanced Machinery’s experience to enhance product finishing with unmatched precision and speed.

Finishing Solutions:

Schuberts UK’s expertise in turn-key finishing systems will ensure products are efficiently coated and dried, meeting the demands of modern consumers.

Sustainability Focus:

The venture is committed to eco-friendly practices, with a focus on reducing energy use and minimizing the environmental footprint throughout the processes.

Customization:

Elevated Finishing will offer customizable solutions to meet the unique needs of all finishing industries, ensuring each product receives the attention and care it deserves.

National US Reach:

With Advanced Machinery’s existing presence and Schuberts UK’s extensive network, Elevated Finishing will provide comprehensive solutions to clients all across the US.

Quotes from Company Leaders:

Coby Johnson, President of Advanced Machinery, shared his excitement: “Elevated Finishing represents a significant step forward in a joint partnership between ourselves and Schuberts. Together with Schuberts UK, we are poised to deliver solutions that will elevate product quality and efficiency to new heights.”

Mark Schubert, Director of Schuberts UK, added, “We are delighted to partner with Advanced Machinery to create Elevated Finishing. Our combined expertise and growth over the last few years in the US market will provide our end users with unparalleled finishing solutions that will set new industry standards.”

Join Us On The Journey

Elevated Finishing has just started its own journey, and both Advanced Machinery and Schuberts invite industry professionals, partners, and clients to join them on this exciting journey for the US market. Stay tuned for further announcements, and be prepared to experience a new era of product finishing excellence and quality. @Ryan Randell will be heading up all technical sales as Director of Elevated Finishing and can be contacted at ryan@elevatedfinishing.com

About Advanced Machinery: Advanced Machinery is a cross-state leader in manufacturing solutions, offering cutting-edge machinery and equipment to the timber and allied industries. With a commitment to innovation and excellence, Advanced Machinery empowers businesses to reach new heights of productivity and efficiency. https://www.advanced-machinery.com/

About Schuberts UK: Schuberts UK is a leading manufacturer and provider of manual and automatic finishing solutions, including the Schubox gas catalytic drying technology. They specialise in custom finishing systems for various industries. With a focus on innovation and sustainability, Schuberts UK helps clients streamline their finishing processes while reducing environmental impact. https://www.schuberts.co.uk/