Profile Mouldings Producer Increases Production With Schuberts Golden Touch

Deep in the countryside, there is a small specialist company producing top quality picture frame mouldings and profiles in softwood and hardwood.

When in spring of this year arsonists struck, their spray shop and old processing equipment was burnt to a cinder, they called Schuberts to get them back up and running as soon as possible.

Although outdated, the old machinery had been well looked after and had produced some of the UK’s finest quality profiles over the years. However, technology and legislation had moved on and Schuberts were able to specify and install some special custom items of equipment.

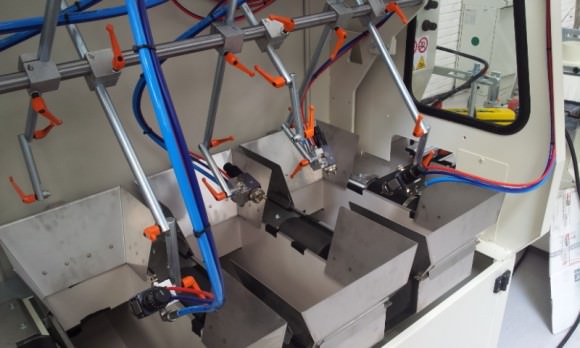

Two new profile coating lines were installed first. These are custom built sanding and spraying lines, specifically designed to accept both short and long lengths of mouldings and to cope with current legislation regarding spray solvent based product, are fully ATEX certified.

Each spray machine is fitted with a double spray circuit and 6 guns in total, allowing complete flexibility and the option of quick colour change.

The sanding machines (one 4 head and one 6 head) have inverter drives on all sanding heads and are fitted with universal adjustment to ensure the perfect pre-sand and de-nibb on a wide range of profile shapes and substrates.

Running at a line speed of up to 35m/min, the limitations of the spray lines is only the speed that the operators can work at!

At the end of both profile spray lines, Schuberts have installed two fully ATEX twin-use spray booth extraction walls. These booths are also fitted with custom canopies, ATEX lighting sets and ducting to atmosphere.

For more information see www.schuberts.co.uk or email sales@schuberts.co.uk