Big Is Beautiful!

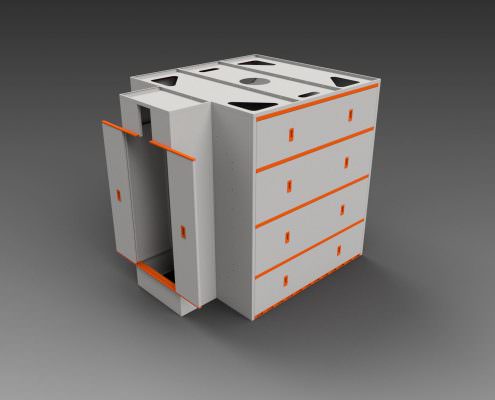

Schuberts have just handed over the largest, highest capacity Schubox ever installed! This fully automatic turn-key curing system is feeding from a through-feed automatic spray machine and stacker.

The Schubox installation is some 17m long end to end and 8m wide and features 2 individual processing lanes.

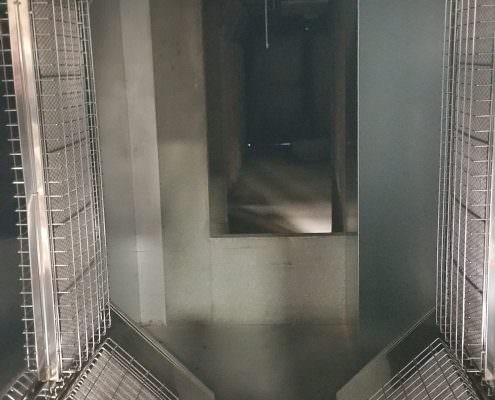

Two automatic inverted floor conveyors are specially designed to pull 8 trolleys of 500kg each at a set (adjustable) rate through the Schubox. That’s 8000kg of product being moved!

Automatic doors on the infeed and outfeed mean the trolleys can be indexed through the system with minimal heat loss.

This gas catalytic technology is designed to cure 1000 microns (1mm!) of wet fire proof paint in a single pass in 90 minutes at 60c. There is no other system on the market that is able to process this film thickness in this time at such a low temperature.

Each full trolley carries 22 wet panels and each lane in the Schubox holds 8 trolleys at a time inside. Based on a single shift and DOUBLE sided coating, this Schuberts installation is capable of processing 800 panels in a single shift!

The Schubox has instantly made a huge impact on production volumes and times. Previously, the coatings were taking 3 days to dry. Now just 90 minutes!

It goes without saying, we’re very proud of this Schubox.

Email sales@schuberts.co.uk for more information on how we can reduce your surface coating drying times across industry.

#finishingsystems #schubox #drying #paintfinishing #automaticspray #automaticspraymachine #schubertsfinishing