One of Canada’s leading manufacturers of wood, steel and GRP doors has recently taken delivery of a new Schuberts manual finishing system and a Giardina automatic spray machine integrated into one special plant.

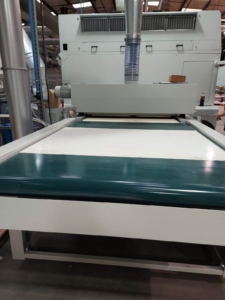

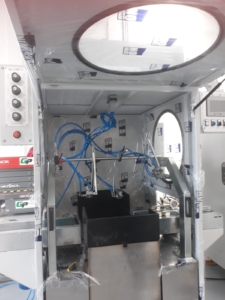

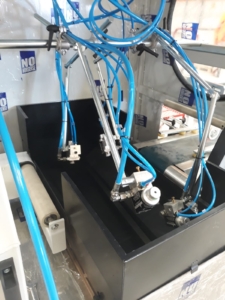

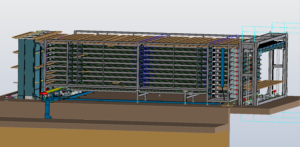

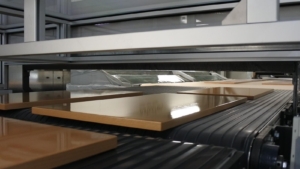

The entire system comprises of a manual spray shop enclosure, flash-off zone, Schubox drying system, paint mixing room, Giardina 416 automatic spray machine, infeed and outfeed conveyors with filtered air systems.

When the customer has volumes of doors and components to spray in one colour, they use the Giardina machine, offload onto trolleys in the flash-off, allow the coating to flow out and then put the trolleys into the Schubox for drying. The guns and pumps have been fitted by and the whole installation looked after by our working partner in Canada, Yorke Towne Supplies.

On smaller volumes, special colours or coatings and 3D products, they hand spray in the spray shop enclosure, then flash-off and then into the Schubox for curing.

This client works with multiple substrates (wood, GRP, PVC etc) and multiple types of 1k, 2k, water and solvent coatings, so truly a universal hybrid finishing system.

For more information, email sales@schuberts.co.uk or contact@yorketowne.com