TFT USA Choose Schuberts As Their Finishing System Supplier

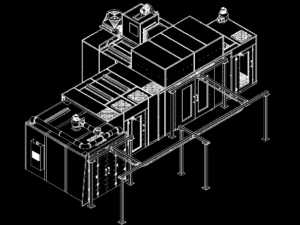

TFT, USA, based in Charlotte NC, have had a complete finishing system installed from Schuberts.

The system comprises of a custom built finishing line and cutting/sanding room. All to ATEX, UL and FM standards.

Designed for steel fabrications, wood, PVC, fibreglass doors (GRP) and a whole host of other substrates, this is a truly flexible finishing system.

Products are either hung on the overhead track and suspended from above or taken inside on trolleys and sprayed on turn-tables.

The spray shop enclosure features full HMI control, automatic booth balancing system, filtered air input and benefits from local HARU, meaning the temperature and cleanliness of the spray shop is maintained at all times.

Once coated, the pieces are taken into the flash-off zone to flow out and vent prior to rapid curing in the Schubox catalytic IR drying system.

The Schubox, running at 38-45c pulls the carrier out of the coating very quickly, without affecting the substrates.

After the Schubox, the pieces are either de-nibbed or ready for further processing.

A paint mix room has been installed for the intermediate storage of coatings, accurate mixing and colour matching.

The cutting/clean room is a separate installation for cutting, cleaning, wiping down and de-nibbing or de-burring on Sandbox downdraft tables.

For more information email sales@schuberts.co.uk