Giardina Profile Coating Line Installed At Timber Door Producer

A new Giardina profile finishing line has been installed by Schuberts at a well known timber and PVC fabricator.

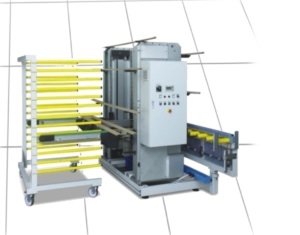

The line consists of infeed conveyor, brush-sanding machine, profile spray machine, automatic stacking system and drying trolleys.

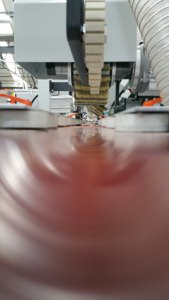

Timber, anything up to 300mm width x 4000mm length can be fed down the profile line by hand, thereafter it is fully automatic.

The multi-headed brush sanding machine is fitted with Flex-trim heads to give an optimal pre-sand and intercoat denibbing. All heads on the sanding machine can be angled, rpm altered and direction of rotation changed, all depending on the substrate and quality required.

The Giardina profile spray machine features double fluid lines, filtered air input and extraction, collection tanks for overspray and 4 automatic spray guns. As the product passes into the spray machine, the piece is ‘read’ and the guns actuate on and off automatically, giving an even and regular coat of paint.

Once coated, the product is then transferred to the stacking system, where the wet profiles are taken and loaded into each arm of a drying rack. This is done fully automatically from top to bottom, with random length and width pieces being no issue for the stacker to deal with.

The complete Giardina line runs at 30m/min and can process over 12,000 lineal metres of profiles per shift, single pass with just 2 operators and will pay for itself in 18 months.

For more information, email sales@schuberts.co.uk