Garden Trellis Company Invest A New Schubert Finishing System

The Garden Trellis Company manufacture and supply a wide range of high quality timber garden products. From affordable ready-made and ready to assemble products, to the most desirable and bespoke custom made garden joinery available, they have it covered.

From their extensive workshop and design centre in Essex they continue to develop new and interesting products and are proud to work with many of the UK’s leading garden designers, landscape gardeners, developers and architects. They design, build and pre-paint a wide range of products for their bespoke customers. They offer site visits, free CAD design service and an installation service with a “clean site guarantee”.

Key to this high quality service is the finishing of the products. To this end, a complete new finishing system has been installed at The Garden Trellis Company. The new system was a scratch install and includes a full overhead conveyor system, support steel work, flow-coating system, spray booth, sanding booth, flash-off, gas catalytic drying zone and humidification system.

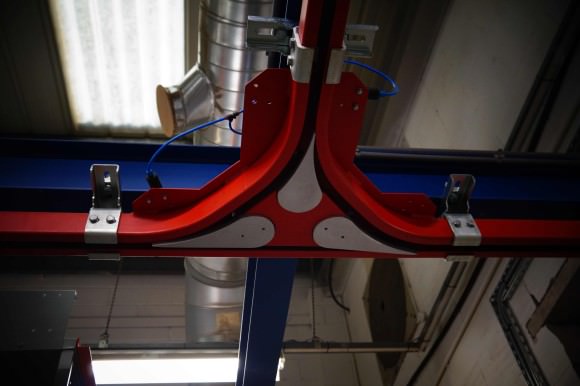

Working at a height of over 3m, the conveyor features multiple trolleys and flight bars to hang the product from. Each conveyor gate is actuated with compressed air, meaning moving the trolleys into the correct position is easy.

A heavy duty automatic lift station takes the strain when product is loaded and unloaded from the line.

The flow-coating liquid is applied with a low pressure spray system and allowed to soak into the structure of the wood. This gives the wood extra external use protection and a better quality finish. Once dried, the base coat is carefully hand applied in front of the spray booth with airmix pumps and guns for an even and regular coating.

To dry and cure the paints, Schuberts installed a 3 lane buffer zone, fitted with long wave gas catalytic infrared heaters and fan sets. This system quickly and evenly cures the waterbased paint in a fraction of the time it would take in ambient conditions. The multi-lane buffer means that dozens of trolleys loaded with product can be dried at the same time. The temperature inside the drying room is at a maximum of 30c, so it doesn’t affect the wood structure or the paint chemistry, yet dries the coatings very quickly with long wave infrared and air movement.

Once dried the product is sanded and cleaned in a sanding booth before being returned for top-coat paint application, drying and then finally off the line for packing and despatch.

Along with the finishing system, Schuberts installed a humidification system. This actively monitors and controls the moisture content of the air within the finishing shop. This improves the quality of the paint, means the wood is under less stress when coating and drying processes take place and it ensures a high quality, uniform finish can be achieved come rain or shine!

Julian Furness, MD of The Garden Trellis Company, said “A goal of our business is to continually try to improve the quality of our joinery and the efficiency of our factory; the system designed and installed by Schuberts has helped achieve both these. Painted joinery is increasingly popular with customers so the quality of the finish matters more than ever.”

For more information on the range of high quality products from Garden Trellis, please see http://www.gardentrellis.co.uk

To see how Schuberts can design and install a complete finishing system for you, email sales@schuberts.co.uk