R&E Falkingham Invest With Schuberts

R&E Falkingham are a UK manufacturer of high quality timber windows, doors and custom joinery work.

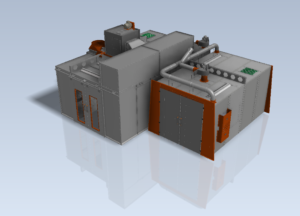

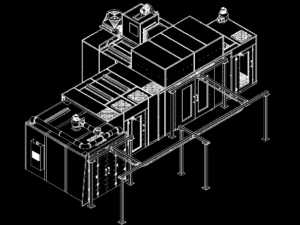

They engaged with Schuberts for a turn-key new finishing system. This involved a sanding booth, with clean air-return systems, a large manual spray booth and a Kit-Cat IR drying system, all integrated into an overhead track system.

The products are manufactured and sanded or de-nibbed in front of an ATEX booth, where the dust is filtered and pushed back into the room as clean air.

The spray booth is a full height, custom-fit unit, with hand-made transition ducting through the wall and out to atmosphere.

Once sprayed the peices go into a Kit-Cat drying tunnel, where direct IR, reflected IR and air movement all combine to dry the coatings very quickly.

All in all, a lovely installation!