Services and Trade Interiors and Contracting, Oman, High Gloss Systems Installed

A new Schuberts double installation has just been commissioned in Muscat, Oman.

This installation was designed for two separate finishing systems within the manufacturing site in Ruwi, Muscat.

Phase 1 featured ATEX rated open spray booths and custom ducting to atmosphere. These booths were fitted with Andreae high efficiency double layer filters. These open booths are used for primers, base coats, stains and satin finishes on GRP, glass, wood and plastic.

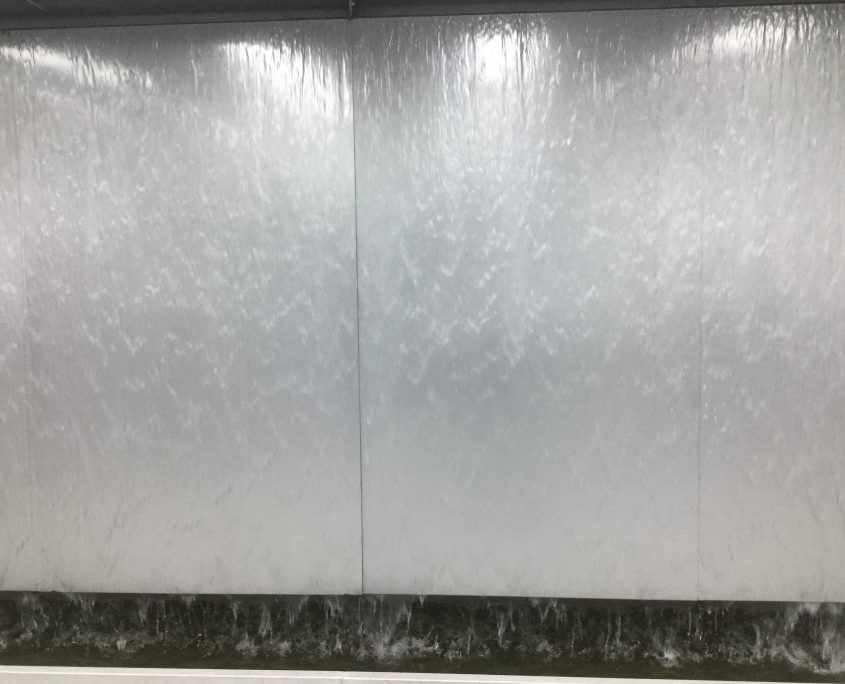

Phase 2 was a large complete water-wash stainless steel installation for solvent based gloss product onto wood, GRP and glass substrates.

The 6000mm x 7000mm spray enclosure has a double filtration system for the air into the spray zone. Firstly, air from outside the factory was filtered by an existing air handling system and then the air undergoes a further cleaning through capture and hold air input filters on top of the Schubert spray enclosure.

The paints and lacquers can be applied by up to 3 sprayers working on rotating tables, against a full water-wash extraction system. A cascade of water takes away the overspray with recirculated water flow into a base hopper tank for overspray capture. This system has a high capacity recirculated water flow with fresh water top-up system, allowing increased flow to the scrubber nozzles, whilst minimising the volume of water inside the water wash spray booth.

Lighting is provided by roof and wall 1000 lux blue/white flicker free sky-white lighting systems. This is the closest to natural light and perfect for the spray application of clear coats and pigmented paints onto a variety of substrates, including solid wood, veneers and glass.

All intermediate storage of paint tins is inside a special paint mix room, adjoining the spray enclosure. This features a bunded floor, ATEX lighting, ATEX heating and permanent extraction to atmosphere via an ATEX rated fan set and ducting. Also this paint kitchen features explosion relief panels and twin personnel doors for emergency escape routes.

Once sprayed inside the spray shop enclosure, the wet racks of product are transferred into a 12,000mm x 3000mm flash-off zone. This area is to allow the solvent vapours to ‘flash’ prior to being force cured in the Schubox drying system. The flash-off zone is fitted with filtered air input to ensure a clean zone. There are low level, full-length, extraction chambers, ATEX fans and ducting into the Schubox for oxidisation.

After flash-off (5 mins for water based, 10 mins for acid catalysed and 40 mins for high gloss PU), the products are placed inside the Schubox for drying and curing. The Schubox is a long-wave, gas catalytic infra red drying system, designed to run at low temperatures and cure wet coatings very quickly. This Schubox in Oman, runs at 40c and cures solvent polyurethanes in 45 minutes (compared to 2 days in the past!). The Schubox has filtered air input, air movement, full stainless steel construction and custom made infeed and outfeed doors.

For more information on high gloss finishing systems for wood and glass, spray booths, rapid drying and all Schubert systems, email sales@schuberts.co.uk

Leave a Reply

Want to join the discussion?Feel free to contribute!