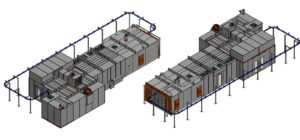

A significant, new, turn-key finishing installation has been commissioned at one of the UK’s leading GRP door slab, ancillaries and plastic components manufacturers.

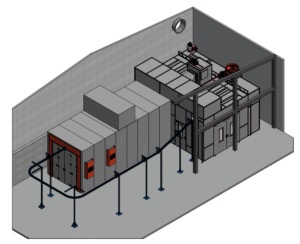

The equipment comprises of a stand-alone horizontal automatic brush preparation machine. This through-feed machine uses Flex-Trim abrasive brushes to prepare the surface of the substrate. This then allows the slabs to be cleaned and then chemically prepared, ahead of coating. The through-feed brushing machine runs at 3m/min, meaning 380-400 sides can be processed per shift.

A load/unload automatic lifting station, when product up to 100kg each can be loaded and unloaded from the line with a single man.

The overhead conveyor is installed throughout the complete installation and with a max load on each 4 wheeled trolley of 200kg and a 90 degree sprung fitting for rotation.

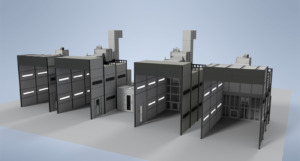

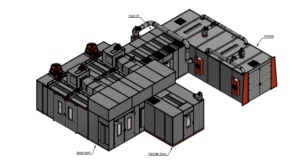

Once loaded onto the line, a full ATEX rated spray enclosure with filtered air input and auto balance smart system has been installed for the spraying of the products. Individual silder divider panels are used to split up the spray zone into sector specific areas, allowing each of the potential 2 sprayers to spray at the same time.

Filtered air input, means all the incoming air for the spray process has airborne contamination removed, meaning no inclusions on the wet pieces being coated.

The inverter driven input and extract ATEX rated centrif fans are connected directly the PLC in the control panel and constantly alter their output depending on air pressures, filter condition and spray velocity required.

Once sprayed, the pieces go into a separate flash-off zone, where the coating is allowed to settle, vent and find its own level. Again, filtered air input means the wet product is kept clean and clear of particulate.

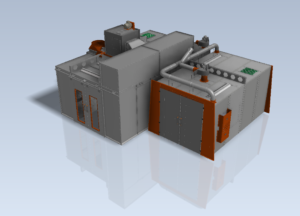

After the flash-off, a custom dimensioned Schubox is utilised for very rapid drying of the coatings. Running at just 36c, the gas catalytic IR heaters produce long wave infrared and along with a unique airflow inside the Schubox, the coatings are dried very quickly – around 45 minutes compared to 18 hours in ambient.

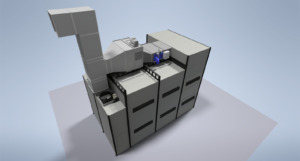

A dedicated ATEX rated paint mix room completes the installation. Bunded floor, ATEX heating, permanent extraction, filtered air, doors, work bench and ducting all feature in the PMR.

For more information on custom design manual and automatic spray finishing systems, email sales@schuberts.co.uk