As part of the continual growth and advancement in the UK, Schuberts have yet again re-invested in the latest finishing technology. Schuberts are the ONLY manufacturer and supplier of finishing equipment in the UK with a production-spec Test Centre, Lab and Training Facility.

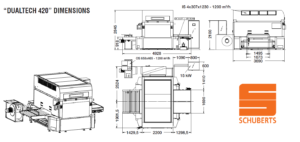

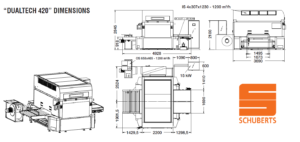

This month, we Schuberts the delivery and installation of the new Giardina Dualtech 420, fully automatic through-feed spray machine system. This machine is suitable for wood, metal, plastics, glass, composites and many other industries. It will accept 1k waterbased, 1k solvent based, 2k waterbased, 2k solvent based and lots of other sprayable coatings.

Capable of running up to 8m/min, it boasts multiple wet spray circuits, 8 Wagner GA400 guns, full self-cleaning paint recovery belt and a whole host of other features that set it aside from the normal competition. With inverter driven fans the system can be tailored to the customers exact requirements. Made ready for Industry 4.0, the Giardina machine is prepared for the future!

All Dualtech spray machines have in common is the top quality of key technical features, including two opposing painting arms and a large cabin which guarantees an optimal application on both the panel’s surface and edges.

Other noteworthy features are the technology to recover paint from the conveyor belt and the latter’s cleaning system, unequalled solutions in terms of extremely low washing solvent consumption, a longer belt service life and a very simple operation.

All Dualtech machines can be fitted with accessories and technological solutions to further increase their flexibility, productivity and reliability. This includes the “Dualfast”, the system that allows you to change guns – and hence the spraying circuit – in less than 60 seconds, thereby maintaining optimal working conditions; the option of the PLC controlled vertical positioning system of the guns also guarantees excellent painting cycle repeatability; the electronic control for the ventilation inside the spray chamber which is required for extending the efficiency and operating time of the spray machine. All versions are available with a “Dry” or “Wet” solid particulate disposal system.

Giardina Dualtech 420 brochure Dualtech 420_GB Brochure

For more information, email sales@schuberts.co.uk