Composite Door Manufacture Installs Second Schubert Finishing System

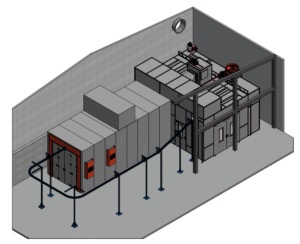

The UK’s fastest growing and probably best-know producer of composite GRP doors has taken delivery of a second turn-key bespoke finishing system from Schuberts.

The line incorporates an overhead conveyor track, spray shop clean room with filtered air input and extract, flash-off zone and Schubox drying technology.

Once prepped and cleaned, the doors are hung onto the conveyor and moved into the spray shop for coating. Both the air input and extraction are inverter driven, giving a balanced air flow irrespective of the condition of the filters. The sensors fitted to the spray shop will even tell the operators when to change the filters.

The flash-off section allows the coating to flow and settle before going into the catalytic IR zone for rapid drying in about 45 minutes.

Once dried, the products are taken off the line and moved into the rest of the factory production system.