RW have a dedicated in-house team of master craftsmen across two joinery workshops, and confidently deliver luxurious one-off pieces to an impeccable standard. Indeed, this precise level of finish is what so often influences their clients’ decision to work with them. With everything custom built, their dedicated joiners cater to requests ranging from custom kitchens, libraries and dressing rooms, to curved work, paneling, exquisite veneers, inlaying and polishing.

This capability is no longer commonplace in the industry and allows RW to maintain excellent standards of workmanship.

Complementing their joinery shops, for requests outside our usual productions, they have developed longstanding relationships with skilled subcontractors that equally work to their rigorous standards.

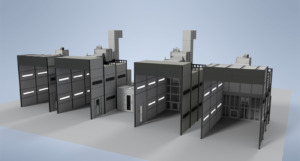

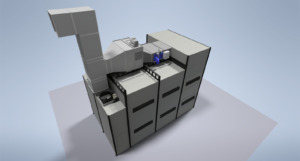

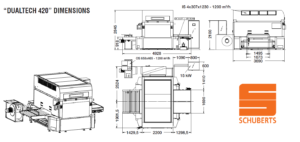

Adding to the very high levels of workmanship, they have just taken delivery of a custom-spec finishing shop from Schuberts.

Every single element of this new system was specifically designed and built for this site and the customers strict requirements, with tolerances and specification to make your eyes water!

-Preparation sanding/denibbing room with full wall extract and filtered cube system back into the factory, along with our Sandbox downdraft benches.

-Spray shop enclosure with full inverter-driven air balance, filtered air input, ATEX rated components and hooked up to twin biomass boiler hot water coils to give the perfect spray temperatures all year round via an HMI touchscreen.

A special multi-leaf hidden divider system allows either the spray shop to be used as one very large zone, or to be used in increments as they see fit.

-Paint mix room, twin doors, with bunded floor, ATEX heating, filtered air input and bled extraction system.

-Drying room with variable air flow, varible heat through biomass boiler hot water coils, again via HMI touchscreen.

The fit, the finish, the quality of materials and components is there in spades and a system that will serve many years of fantastic service to the client.

For more information about Schuberts’ custom finishing systems, email sales@schuberts.co.uk