Revolutionizing Door Finishing: Schuberts’ Game-Changing System

🚪✨ Revolutionizing Door Finishing: Schuberts’ Game-Changing System! ✨🚪

🌟 Step into the world of Schuberts, where innovation meets craftsmanship! 🌟

🛠️ Imagine a realm where every detail of door finishing is elevated to perfection. Well, that’s precisely what Schuberts, the renowned door manufacturer, has achieved with their latest installation: a cutting-edge Door Finishing System!

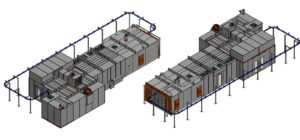

🔄 Picture this: An overhead conveyor system seamlessly guiding doors through each stage of the finishing process. No more manual handling, no more inefficiencies. Just smooth, precise movement ensuring every door receives the attention it deserves.

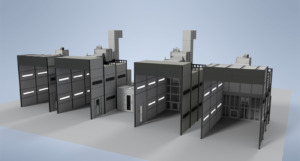

💨 As the doors glide through the system, they enter the spray booth enclosure, where a symphony of precision unfolds. The sprayers delicately coat each door with the perfect layer of finish, ensuring uniformity and excellence in every application.

🌬️ But wait, there’s more! As the freshly coated doors emerge from the spray booth, they’re not left to languish. Instead, they enter the flash-off system, a revolutionary feature allowing for quick venting and flow-out without compromising quality. Efficiency meets quality, transforming turnaround times like never before!

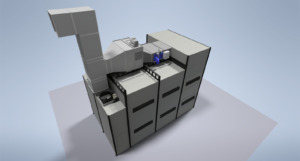

💡 And the pièce de résistance? The Schubox Gas Catalytic IR Drying System! Gone are the days of waiting for doors to dry. Thanks to this ingenious invention, doors are swiftly whisked into the individual drying chamber, where a precise balance of airflow and temperature ensures rapid, flawless drying. In no time, doors emerge, ready to dazzle with their impeccable finish!

📈 The impact? Nothing short of transformative! Overnight, the clients business has undergone a metamorphosis. What was once a labor-intensive, time-consuming process has become a model of efficiency and excellence. Orders are fulfilled faster, quality is unparalleled, and customer satisfaction soars to new heights!

🌟 Schuberts’ Door Finishing System isn’t just a game-changer; it’s a testament to the power of innovation in craftsmanship. With every door that passes through its seamless process, Schuberts reaffirms its commitment to excellence, setting new standards in the finishing industry.

✨ Step through the doors of possibility with Schuberts, where innovation opens new horizons and perfection is just a finishing touch away! ✨