Compsite Slab Manufacturer Invests With New Finishing System

Thrilled to announce a groundbreaking enhancement at a leading UK manufacturer of composite products! Thanks to their partnership with Schuberts, they have revolutionized our production capabilities, setting new standards in composite slab finishing.

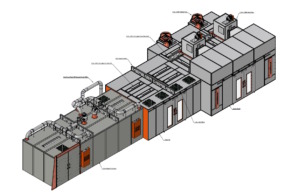

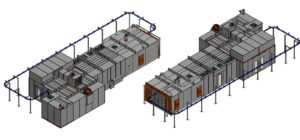

🌟 A Cutting-Edge Spray Shop Enclosure with Air Balance System, Flash-Off Zone, and Schubox Drying System! 🌟

This game-changing setup is designed to optimize efficiency, elevate quality, and ensure unmatched precision in every composite product they deliver.

🎨 The Advanced Air Balance System: Guarantees precise spraying conditions, enhancing consistency and minimizing waste.

💨 The Dedicated Flash-Off Zone: Accelerates flow-out times, allowing for faster turnaround without compromising on quality or contamination.

🔥 The Schubox CIR Drying System: A pinnacle of innovation, it not only speeds up the drying process but also reduces energy consumption, aligning with their commitment to sustainability.

With hundreds of individual components, this system is a real eye-opener!

The client is not just manufacturing products; they are pioneering the future of composite slab finishing technology. This investment underscores their dedication to pushing boundaries and delivering excellence at every turn.

Excited to witness the transformative impact these advancements will have on their products and, more importantly, on the experiences of their cherished customers. Stay tuned for more updates as we continue to redefine what’s possible in the world of composite slabs!

#InnovationRedefined #schuberts #CompositeRevolution #SchubertsPartnership #finishingdoneright #AdvancedManufacturing #QualityCraftsmanship